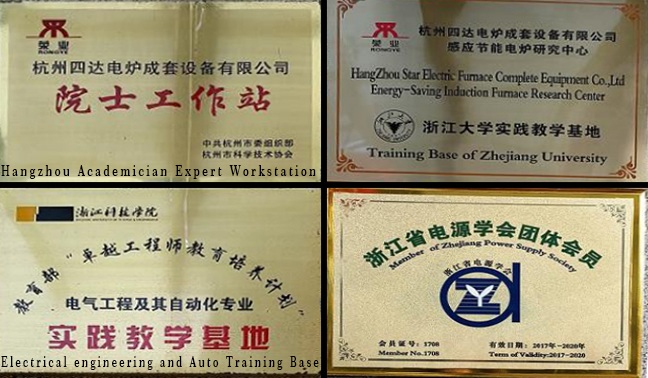

Hangzhou Star Electric Furnace Complete Equipment Co., Ltd, founded in 1995, is the largest professional manufacturer of mid-frequency induction melting furnace and induction heating equipment in China. We have offices, laboratories, research & development center, and production & processing workshops, covering an area of 45,000 m2. And we have a provincial-level R&D center authorized by Zhejiang Province, Provincial Patent Demonstration Units, Hangzhou Academician Expert Workstation and other professional R & D institutions. Owning more than 40 patented technologies with independent intellectual property rights. We are the largest manufacturer of mid-frequency induction furnaces in China.

Our group consists of Doctor Advisors, Professors, Doctors, Masters, undergraduates and experienced engineers. They are all engaged in university education or post-graduate study in Power Electronics Technology in Zhejiang University for many years with a strong professional foundation. They have been working in the field of induction heating technology over the years, and has rich practical experience. At the same time, maintain close technical cooperation with the Zhejiang University, Hangzhou Dianzi University, Nanjing University of Aeronautics & Astronautics and other well-known colleges and universities, with comprehensive technical research and development ability.

The Company develops and produces the medium frequency induction furnace system from 0.5MT to 90MT, and the medium frequency power system from 250KW to 36000kW. Ultra-sonic IGBT inverters (up to the frequency of 50kHZ) and high-frequency MOSFET inverters (up to the frequency of 400kHZ) , which are ideal and advanced for metal heat treatment for small metal parts. And producds are the optimum alternative for vacuum-tube power supply. Induction heating power supply on many occasions is also reasonable choice instead of traditional resistor furnace, gas-fuel furnace and diesel fuel furnace. It can also indirectly heat non-metallic materials by heating metal drums, pipes, etc. with series advantages such as high reliability, low energy consumption, small size, pollution-free, high heating rate, less burning loss, and so on. Especially its heating rate, heating temperature, heating depth and heating region are very easy to be controlled, so induction heating mode has been very popular in metal heat treatment industry.

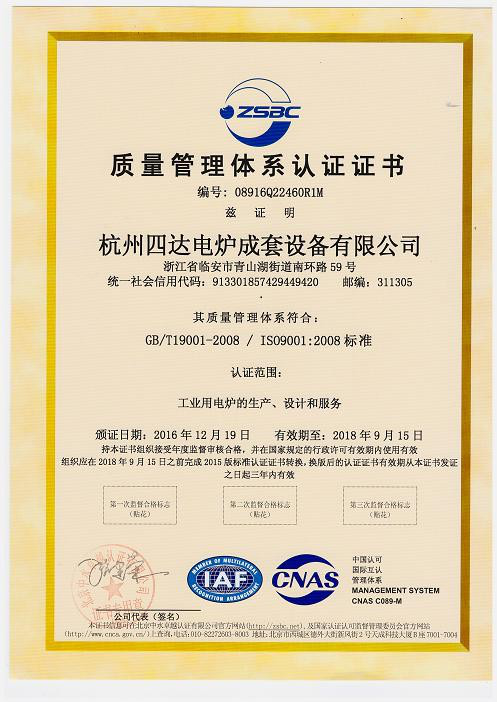

Since the inception, the company has been pursuing a management policy of quality first, technology leadership, and service-oriented. It is committed to the development, application, and promotion of induction heating technology and continues to innovate:

In 2001: China first 12-pulse 6000k/8t MF induction furnace system

In 2003: China first 12-pulse 8000kw/12t MF induction furnace system

In 2005: China first 24-pulse 12000kw/20t MF induction furnace system

In 2006: China first 12-pulse 5000kw/10t induction melting furnace system

In 2007: China first 24-pulse 18000kw/40t MF induction furnace system

In 2009: China first 15,000kw/40t nickel-chromium alloy melting furnace system

In 2010: China first 12-pulse 6000kw/1000Hz continuous casting and rolling on-line induction heating furnace system

In 2011: China first 24-pulse 27000kw/70t MF induction furnace system

In 2016: China first 24-pulse 30000kW/80t MF induction furnace system

In 2017: China first 24-pulse 36000kW/90t MF induction furnace system