Hangzhou Star Electric Furnace has been the competent market leadership in the field of induction furnace equipment to serve the steel industry (structural steel, alloy steel, stainless steel and so on), has been supplying the induction furnace body from capacity of 3MT to 90MT and also the solid state power supply system from 2000kW to 40000kW. As a leader induction furnace manufacturer in China, Hangzhou Star has exported the induction furnace to Europe, South America, Middle East, Latin America and Asia markets and we are the biggest induction furnace manufacturer in China.

The advantage of Hangzhou Star Electric Furnace is that we have a full set of design, engineering, installation, maintenance and repair services all over the world. Hangzhou Star can provide the best technical design of a fully integrated system for induction melting, holding, and induction heating applications, and has a stronger team of experienced induction furnace specialists. We have a full set of design, engineering, installation, maintenance and repair services.

Features:

The stable working performance for the SCR inverter with the parallel circuit;

The 24-pulse or 12-pulse design control systems for large-capacity power supplies (2000kW to 40000kW) for low harmonic interference;

Power supply with a max. capacity of 40000 kW (the first invention in China);

Advanced design of filter inductor has ensured the safety of SCR;

The power factor is 0.95 under all operating conditions;

All-digital control system with high accuracy and self-diagnostics;

Leak detection system with alarm and shutdown function to ensure the safe operation of the power supply;

Simply start and stop the entire control system;

Special rectifier furnace transformer is matched with suitable solid state power supply;

Safety control of water circuit flow and temperature;

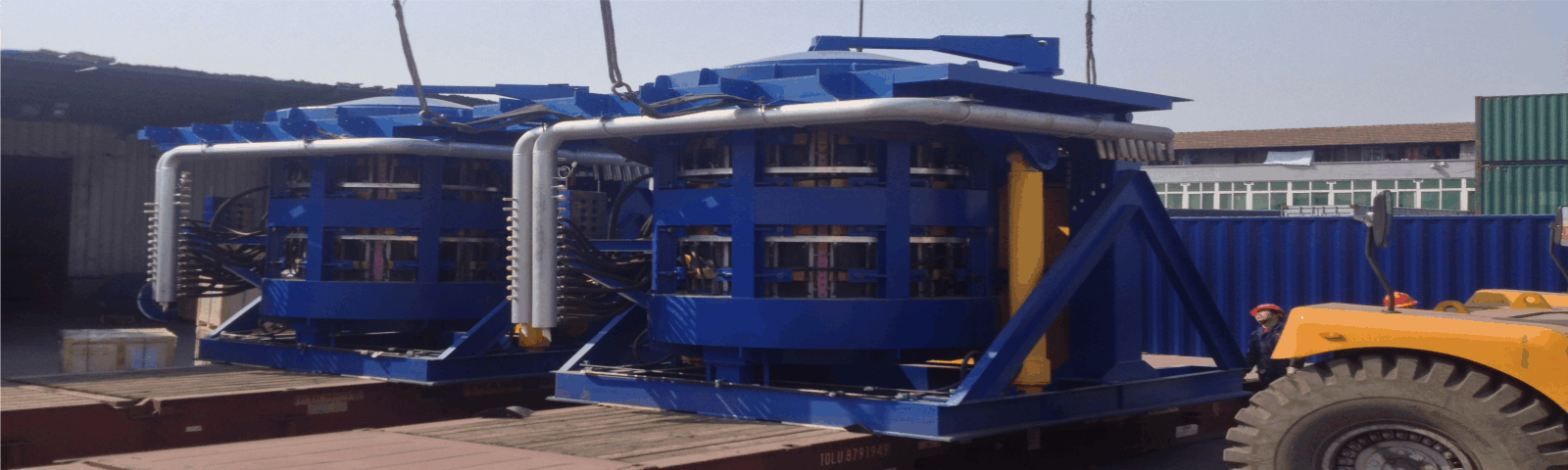

Steel shell furnace body is the best design for induction furnace in the world;

Steel structure design is used for solid furnace body from 3MT to 90MT, with easier access due to the open frame;

Thicker high-temperature top and bottom blocks can last longer and stay shape suitable for the furnace;

Low loss water cooled shunts;

Bench type furnace platform;

Lining push-out system can be installed (optional);

Maintenance friendly arrangement.

In 2001: China first 12-pulse 6000kW/8t MF induction furnace.

In 2003: China first 12 pulse 8000kW/12t MF induction furnace.

In 2005: China first 24-pulse 12000kW/20t MF induction furnace.

In 2007: China first 24-pulse 18000kW/40t MF induction furnace.

In 2011: China first 24-pulse 27000kW/70t MF induction furnace.

In 2016: China first 24-pulse 30000kW/80t MF induction furnace.

In 2017: China first 24-pulse 36000kW/90t MF induction furnace.

With the improving energy-saving power requirements of induction furnace, our company has gradually explored the improvement on energy-saving, the features of new energy-saving DC Chock are as follows:

All conductive wire packages adopt aluminum foil winding structure, with no water, no oil cooling, and they are cooled by air (fan is added), commonly known as dry-type smoothing DC Chock. This type of smoothing reactor is used in large-tonnage induction melting furnaces, and the reaction effect is very satisfactory, the energy saving is relatively large, and the energy saving per ton of steel is 20 to 40 kWh/t.

The dry-type DC Chock has simple structure, no oil, safe and reliable operation, large inductance, good linearity, low noise and small loss, and maintenance-free. However, it is bulky, covers a large area, and has a large magnetic flux leakage range, and large electromagnetic interference to the surrounding electrical equipment and it has high power loss. This DC Chock is particularly suitable for high-power melting customers.

Medium Frequency Induction Melting Furnace Series (3~90t /2000~40000 kW)

The melting furnace series is basically designed according to the capacity level. The following table lists the standard parameters for induction furnaces used for steel, aluminum, and steel (iron) water insulation. For some foundry users, the rated power can be appropriately reduced without pursuing smelting time.

Main technical specifications of induction furnace for melting steel scrap

| Rated capacity ( t ) | Rated power ( kW ) | Rated frequency ( Hz ) | Transformer configuration | Pulses | Coil voltage ( V ) | Melting rate (t / h) (1600 ℃) | Energy consumption (kWh / t) | |

| Capacity ( kVA ) | Secondary voltage ( V ) | |||||||

| 3 | 2300 | 500 | 2500 | 3φ690V | 6 | 2400 | 3.0 | 600±4% |

| 5 | 3700 | 500 | 4000 | 3φ1000V | 6 | 3200 | 5.0 | 590±4% |

| 10 | 6300 | 500 | 7000 | 6φ1000V | 12 | 3200 | 10 | 580±4% |

| 12 | 7200 | 250 | 8000 | 6φ1250V | 12 | 4200 | 11 | 560±4% |

| 15 | 9000 | 250 | 2×5000 | 2×6φ1250V | 24 | 4200 | 14 | 550±4% |

| 20 | 12000 | 250 | 2×6300 | 2×6φ1250V | 24 | 4200 | 18 | 550±4% |

| 25 | 15000 | 250 | 2×8000 | 2×6φ1250V | 24 | 4200 | 22 | 540±5% |

| 30 | 17000 | 150 | 2×9000 | 2×6φ1650V | 24 | 4800 | 26 | 530±5% |

| 40 | 20000 | 150 | 2×11000 | 2×6φ1650V | 24 | 4800 | 30 | 530±5% |

| 50 | 24000 | 150 | 2×13000 | 2×6φ1650V | 24 | 5700 | 36 | 520±5% |

| 60 | 27000 | 150 | 2×15000 | 2×6φ1650V | 24 | 5700 | 40 | 520±5% |

| 70 | 30000 | 150 | 2×16000 | 2×6φ2000V | 24 | 5700 | 45 | 510±5% |

| 80 | 36000 | 130 | 2×20000 | 2×6φ2000V | 24 | 6100 | 55 | 510±5% |

| 90 | 40000 | 130 | 2×22000 | 2×6φ2250V | 24 | 6100 | 60 | 510±5% |